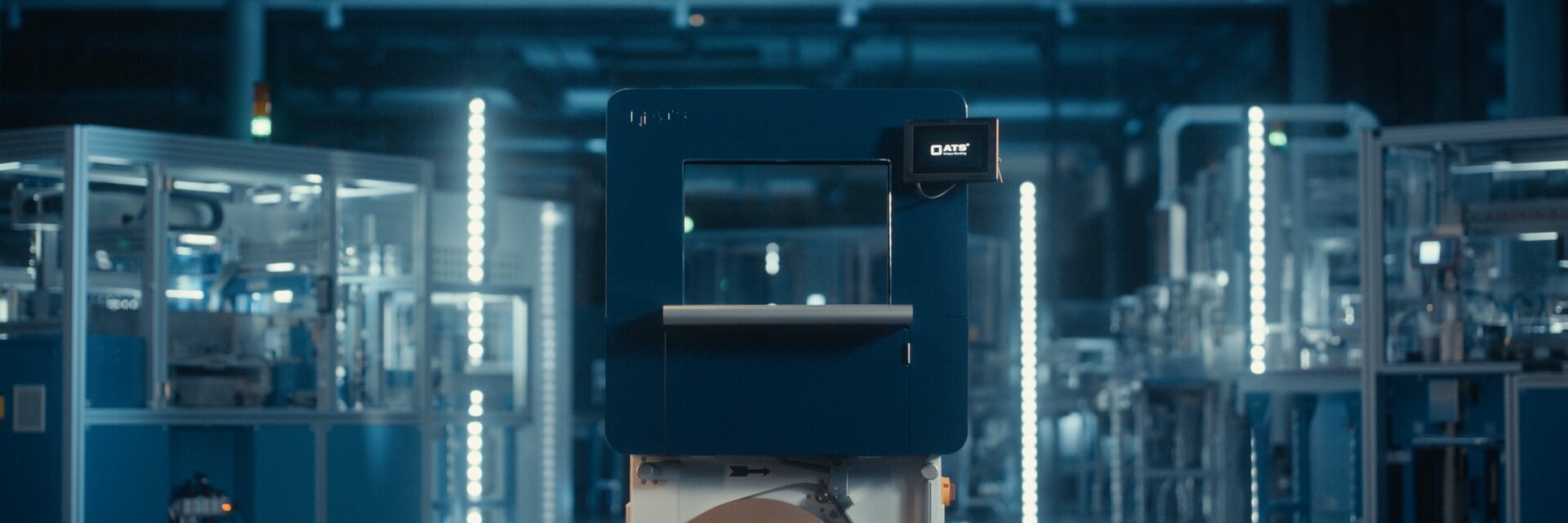

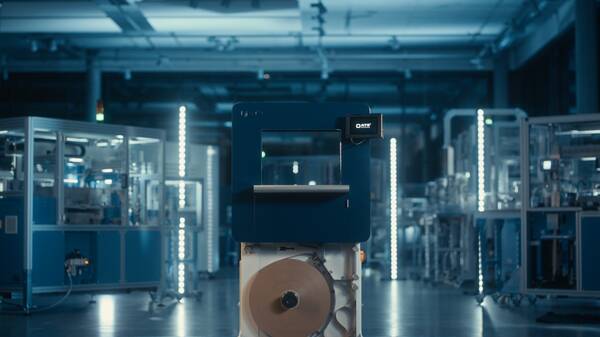

An ATS banding machine that sets new benchmarks.

The successor to the world's best-selling banding machine combines the best of more than 30 years of mechanical engineering experience with state-of-the-art technology. This makes it the most reliable, user-friendly and sophisticated banding machine we have ever built.

A perfect combination of design and function

The robust banding machine is made exclusively of high-quality materials and components. The functionally well thought-out and timeless design ensures that it is a pleasure to operate and makes it a powerful, sophisticated and elegant machine with a high recognition value.

Positive user experience as competitive advantage

A positive user experience increases productivity by avoiding operator errors, reduces training costs and ensures motivated employees. That's why we've invested heavily in design. From the self-explanatory user interface to the height-adjustable table and effortless band change.

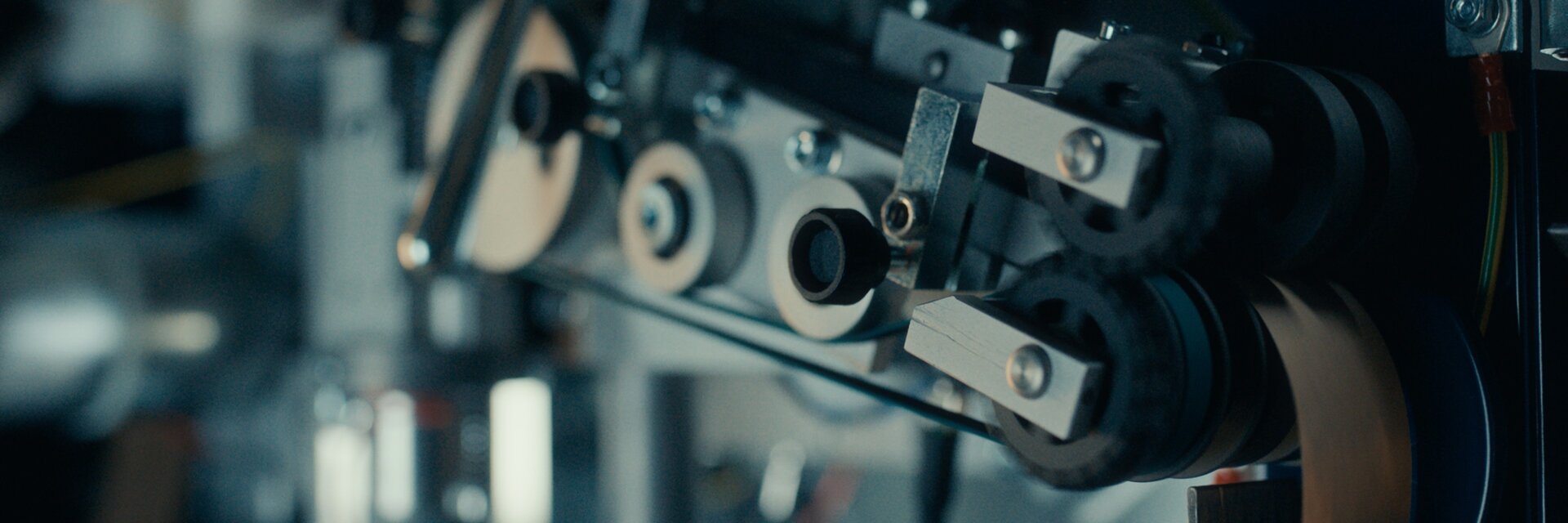

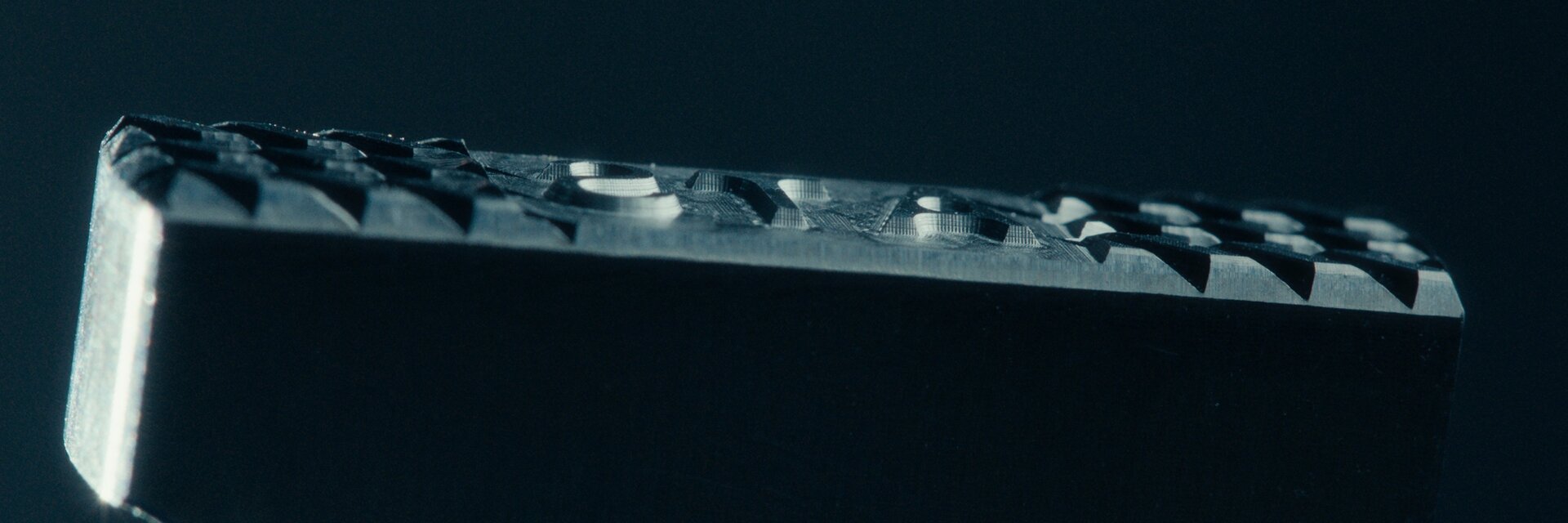

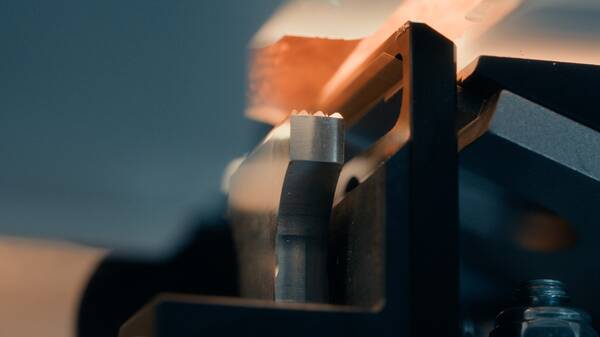

Energy-efficient ultrasonic welding

The patented ultrasonic welding technology makes the US-3000 the most powerful, reliable and energy-efficient banding machine on the market. It consumes 98% less energy than a shrinking machine and ensures consistent welding quality even in extremely cold, dusty or humid conditions. The US-3000 requires no preheating and generates no heat during welding that can damage sensitive products.

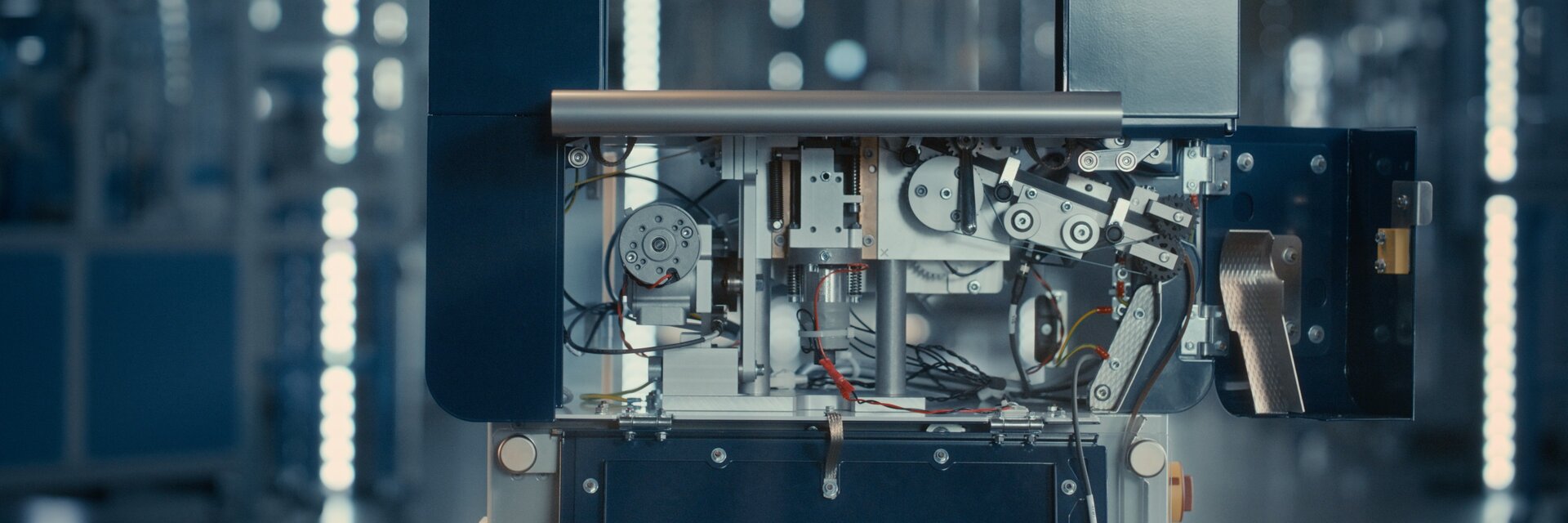

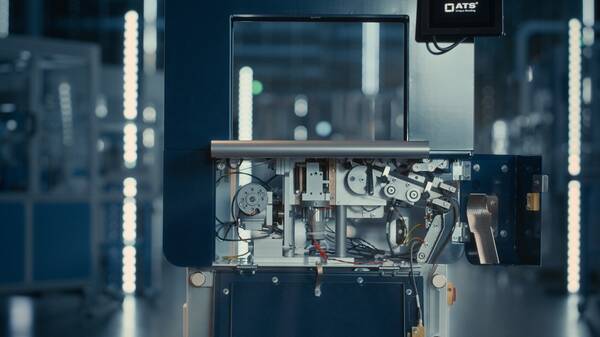

Service and maintenance have never been more efficient

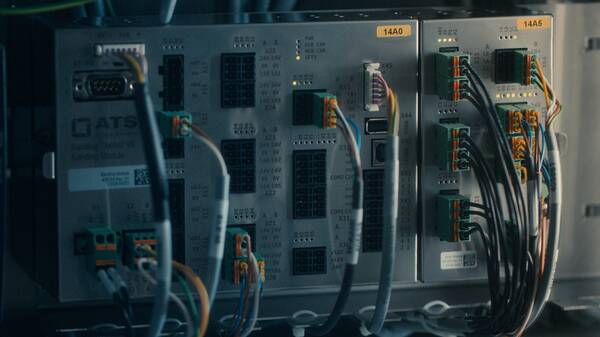

After easy removal of the arch cover and table, all components are conveniently accessible. The clear separation of mechanics and electronics ensures ideal order, structure and overview. Error diagnoses and information for rectification are provided via the HMI.

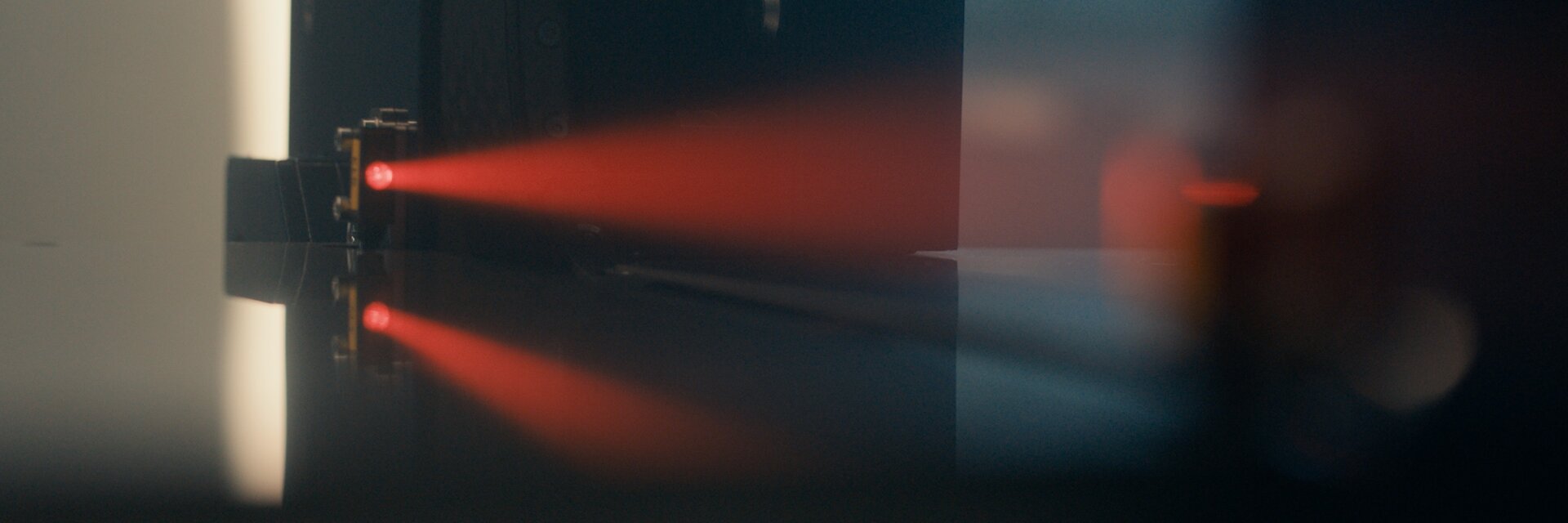

Prepared for standardized data exchange via IO-Link

Built-in temperature, humidity, G-force and vibration noise sensors will in future provide information on the causes of failures and enable predictive maintenance. The controller is prepared for the connection of intelligent sensors and actuators with IO-Link. For example, for the automatic measurement of products via a light barrier.