Ultrasonic banding replaces conventional packaging, reduces your environmental footprint and helps you achieve your sustainability goals.

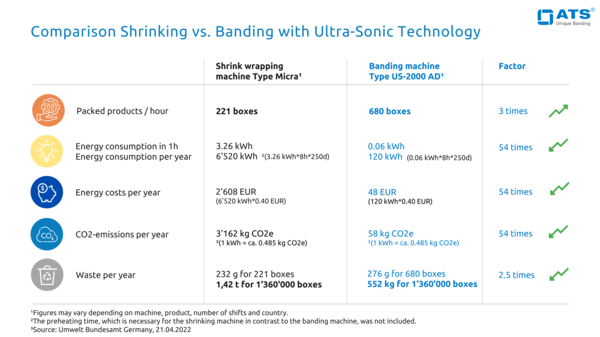

Banding with ultrasonic technology from ATS reduces packaging material to a minimum, cuts energy consumption by 98 percent compared to shrink-wrapping, replaces plastic with paper, automates packaging and eliminates the need for additional labeling. And with ultrasonic banding, you already meet the goals of the EU packaging and labeling regulations that will soon come into force.

Ultrasonic banding can help you achieve your sustainability goals. Banding can help you reduce your environmental footprint in many different ways. From minimizing packaging material to replacing plastic with paper packaging to using the most energy-efficient packaging machines on the market.

Energy-efficient packaging machines - Banding machines with ultrasonic technology are the most energy-efficient packaging machines on the market. Their energy consumption is 98 % lower than that of a shrink wrap machine. Ultrasonic sealing delivers energy directly to the materials being sealed, rather than transferring it in the form of heat energy. The advantages of our ultrasonic technology are

- cold welding,

- immediate readiness for operation,

- low power consumption,

- no risk of injury,

- no adhesives.

Minimize packaging material - Banding always means reducing the packaging material to the absolute minimum. The optionally printed bands replace, for example, poly-tube bags, shrink films, strapping bands, adhesive tapes, cardboard slipcases and additional labels.

Replace plastic packaging with paper - Paper bands from ATS consist of a variety of different paper qualities and barrier coatings with different properties. This makes our paper bands suitable for countless applications, products and environments - even where you would not expect paper at first glance.

Banding increases efficiency in many ways. Banding not only minimizes packaging material when bundling and labeling products, but also supports the automation of processes along the entire value chain. Banding can increase the efficiency of processes in many ways. We have proven automation solutions for, among others, the food industry, fresh fruit and vegetables, logistics, the printing industry, corrugated cardboard industry, pharmaceuticals, cosmetics and many more. Some examples:

- Automatic bundling of products into trade, load or packaging units for simplified handling.

- End-of-line automation: Automatic packaging and preparation of products at the end of the production line for delivery to retailers, wholesalers or points of sale.

- Automatic measuring, aligning, counting or stacking of products through banding systems integrated into the production line.

- Efficient bundling and labeling through integrated printers that print variable information directly onto the band.

- Optimize packaging and returns processes in e-commerce by bundling multiple products for right-size packaging.

- Optimize returns processes in e-commerce by using bands to protect against opening and tampering.

The revision of EU legislation on packaging and packaging waste has three main objectives: Reducing the generation of packaging waste, promoting a circular economy for packaging and promoting the use of recycled materials in packaging. Banding offers solutions for the following three law articles, among others:

- Art. 6 of the EU legislation on packaging and packaging waste requires that all packaging must be recyclable: Our bands made of paper and film are proven to be recyclable.

- Art. 9 of the EU legislation on packaging and packaging waste requires that all packaging is reduced to the minimum necessary by weight and volume: Banding reduces the packaging material to the absolute minimum.

- Art. 11 of the EU legislation on packaging and packaging waste requires harmonized EU-wide labeling of packaging on material composition: Bands can be printed in advance and during banding additionally and just-in-time.